Cylinder Head Services From Southeast Cylinder Head

Inspection is Probably The Most Important Aspect of What We Do

Visual Inspection

It sounds silly but sometimes it can tell you a lot. The biggest problem we run into is when the engine has been replaced with an engine from a different year. Doesn’t mean it won’t run right but parts can be different (torque specs etc).Thickness of the head

Who cares? We Do! If the head is below minimum before we start, this can be serious (particularly for overhead cam heads, cam timing, not enough belt or chain adjustment, valve to piston clearance to name a few).Is the head warped?

Goes back to minimum thickness. If it’s out .025” and it is .005” from minimum thickness, it will be under after we’re done. We can straighten it (we made our own plates 25 years ago long before many people thought of it) but a less costly alternative is a “shim”. We always check before we do anything for availability. There are more aspects to that, if you’d like go to our blog, we’ll discuss them. Disassemble valves, springs, cams, rockers, lifters, if applicable; remove freeze plugs and anything else that is appropriate.Pressure Test

Another critical area There are various methods of pressure testing. We feel sealing the head, pressurizing it and submerging it under water is the best method. Even if you can’t see the leak, you always see the bubbles.

Cleaning

We use a variety of methods but since aluminum heads are the majority of the heads we cover, we’ll discuss that. We use a 2 step treatment consisting of spray wash and ultrasonic cleaning. We knock the heavy stuff off in the spray and finish clean with Ultrasonic. Ultrasonic is good because it gets the inside as well as the outside clean. The following is a before and after view of a pair of Mercedes Benz V-6 heads. These were done as a test so there was no tear down, nor pre-wash, both of which we do automatically every time.

Valve Grinding

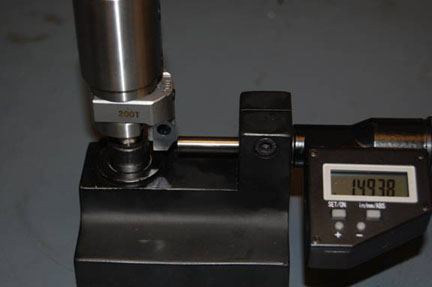

Not a big deal, but an important one. We use a grinder accurate to .0005”. Again it’s a small point but that’s why we’re able to offer our Lifetime Warranty* on all reconditioned and new cylinder heads.Valve Seat Finishing

I don’t want to sit here and point out the pros and cons of cutting the seats versus grinding the seats. There are too many people doing that already. The fact is both have their strong and weak points; that’s why we use both. The advantage to cutting the seat is that you can accurately put the seat angle anywhere on the valve you want. You also can control the depth to within thousandths of an inch.

Resurfacing

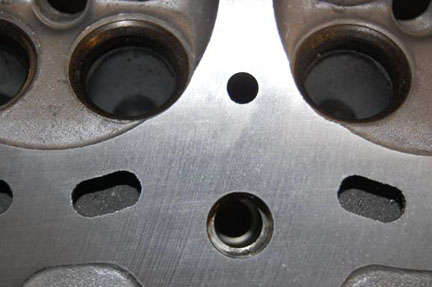

According to “Fel-Pro Gaskets Tec Tip, Understanding Multi-layer Steel (MLS) head Gaskets”: View PDF “Most MLS require a surface smoother than 40Ra……… Regardless of the brand of MLS gasket chosen, for the gasket to seal properly, the finish on the head and block must be flatter and smoother than what has traditionally been required for composite gaskets.” That being said, the following is a comparison between what it should not be and what it should. The first cylinder head is one we received after it had been to a shop, put back on the car, overheated again but the 2nd time it cracked the head. Below is what it shouldn't be.

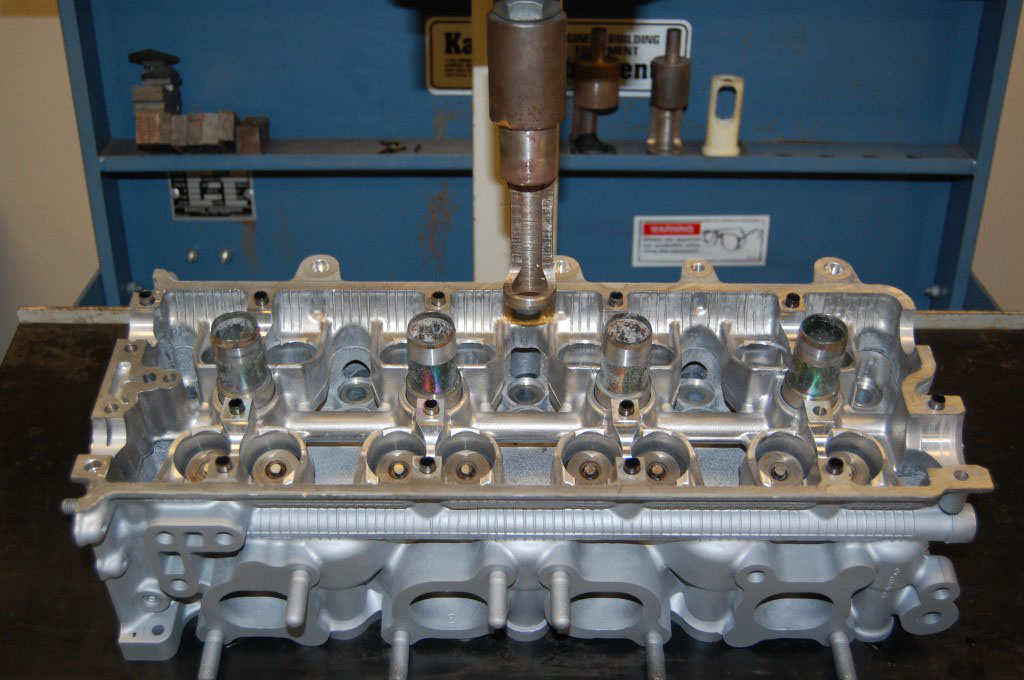

Assembly

Right tool for the right job!